Injection molding machines are essential equipment for various industries in Pakistan, from automotive and electronics to packaging and healthcare. Understanding the factors affecting injection molding machine prices is crucial for businesses looking to invest in this technology. This comprehensive guide provides valuable insights into the price range, key considerations, and factors influencing the cost of injection molding machines in Pakistan.

Factors Affecting Injection Molding Machine Price in Pakistan

Several factors influence the price of injection molding machines in the Pakistani market. These factors include:

- Machine Size and Clamping Force: Larger machines with higher clamping force generally command higher prices due to their increased production capacity and ability to handle larger molds.

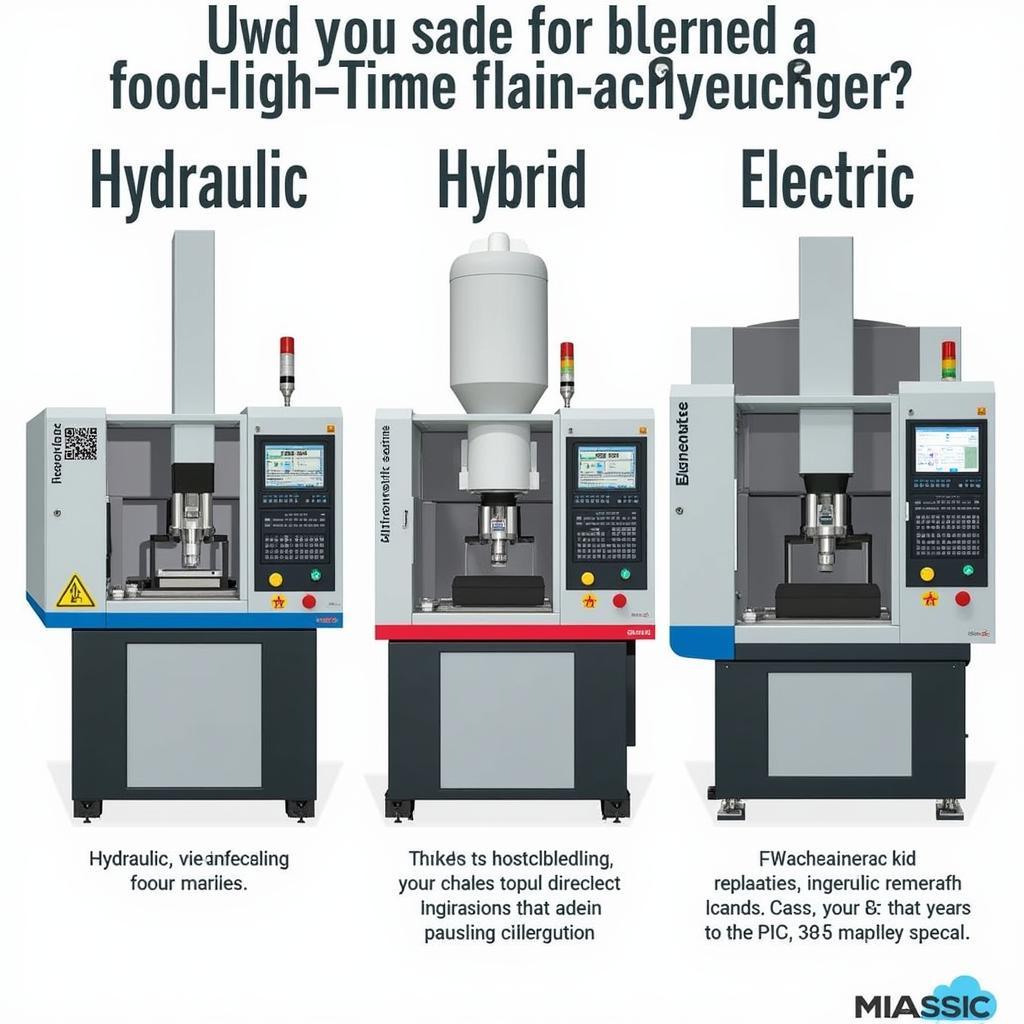

- Injection Unit Type: Hydraulic, hybrid, and electric injection molding machines are available. Electric machines are typically more expensive than hydraulic counterparts but offer greater precision, energy efficiency, and faster cycle times.

- Machine Features and Automation: Advanced features, such as servo-driven systems, closed-loop controls, and automation capabilities, can significantly impact the price.

- Brand Reputation and Country of Origin: Established brands from technologically advanced countries often have higher price points due to their reputation for quality, reliability, and after-sales service.

- New or Used Machines: Used injection molding machines are available at lower prices than brand-new models. However, purchasing used equipment requires careful inspection and consideration of potential maintenance costs.

- Customization Requirements: Customized machines tailored to specific production needs will generally have a higher price tag than standard models.

Types of Injection Molding Machines

Types of Injection Molding Machines

Understanding the Price Range

The price of injection molding machines in Pakistan can vary significantly depending on the factors mentioned above.

- Small to Medium-Sized Machines: Basic hydraulic machines with lower clamping force can range from [Price Range 1] for used models to [Price Range 2] for new ones.

- Large-Sized Machines: Larger machines with higher clamping force and advanced features can range from [Price Range 3] to [Price Range 4] or more.

- Electric Injection Molding Machines: Electric machines, known for their precision and energy efficiency, typically start at [Price Range 5] and can go up to [Price Range 6] or higher depending on specifications.

It’s important to note that these are approximate price ranges, and actual costs can vary based on supplier pricing, currency fluctuations, and market demand.

Benefits of Investing in an Injection Molding Machine

Despite the initial investment, injection molding machines offer several benefits for businesses in Pakistan:

- High Production Output: Injection molding facilitates high-volume production, enabling manufacturers to meet increasing demand efficiently.

- Design Flexibility: The process allows for complex designs and intricate details, expanding product possibilities.

- Cost-Effective Production: Once the initial setup is complete, injection molding offers a low cost per unit, especially for large production runs.

- High-Quality Products: Injection molding produces consistent, high-quality parts with excellent dimensional accuracy and surface finish.

- Versatility in Materials: A wide range of thermoplastic and some thermosetting polymers can be used, providing material versatility for diverse applications.

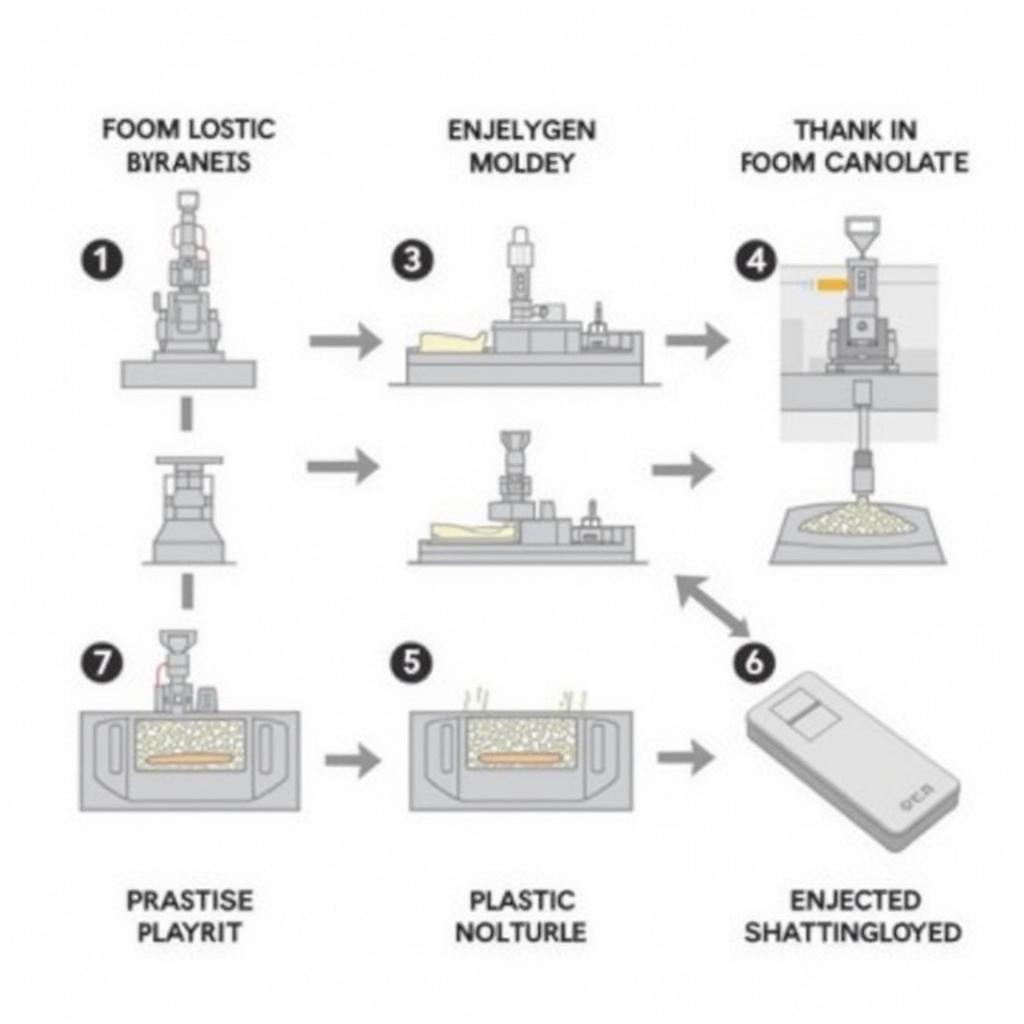

Injection Molding Process in Action

Injection Molding Process in Action

Tips for Choosing the Right Injection Molding Machine

Selecting the appropriate injection molding machine is crucial for maximizing return on investment. Consider the following factors:

- Production Requirements: Evaluate current and future production needs, including projected volumes, part sizes, and complexity.

- Material Compatibility: Determine the types of plastics required for production and ensure the chosen machine can handle them effectively.

- Budget Considerations: Establish a clear budget and explore financing options to make informed decisions.

- Supplier Reputation: Research and choose reputable suppliers with a proven track record of providing reliable machines and excellent after-sales support.

- Energy Efficiency: Consider energy-efficient models to reduce operating costs in the long run.

Conclusion

Investing in the right injection molding machine is a significant decision for businesses in Pakistan. By understanding the factors influencing price, exploring available options, and carefully evaluating production needs, companies can make informed choices that align with their budget and long-term goals. For businesses looking to optimize their manufacturing processes and enhance competitiveness, injection molding technology offers a compelling solution.

FAQs

Q: What are the leading brands of injection molding machines in Pakistan?

A: Several reputable international brands are available in Pakistan, along with local manufacturers. Some well-known names include [List 3-4 Leading Brands].

Q: What are the typical power requirements for injection molding machines?

A: Power requirements vary depending on machine size and capabilities. Generally, machines operate on three-phase power supply ranging from [Power Range in kW].

Q: What types of industries benefit most from injection molding?

A: Injection molding is highly advantageous for various sectors, including packaging, automotive, electronics, consumer goods, healthcare, and more.

Q: Is it better to buy a new or used injection molding machine?

A: The decision depends on budget constraints, required specifications, and risk tolerance. New machines offer the latest technology and warranty but come at a higher price. Used machines can be cost-effective but require thorough inspection.

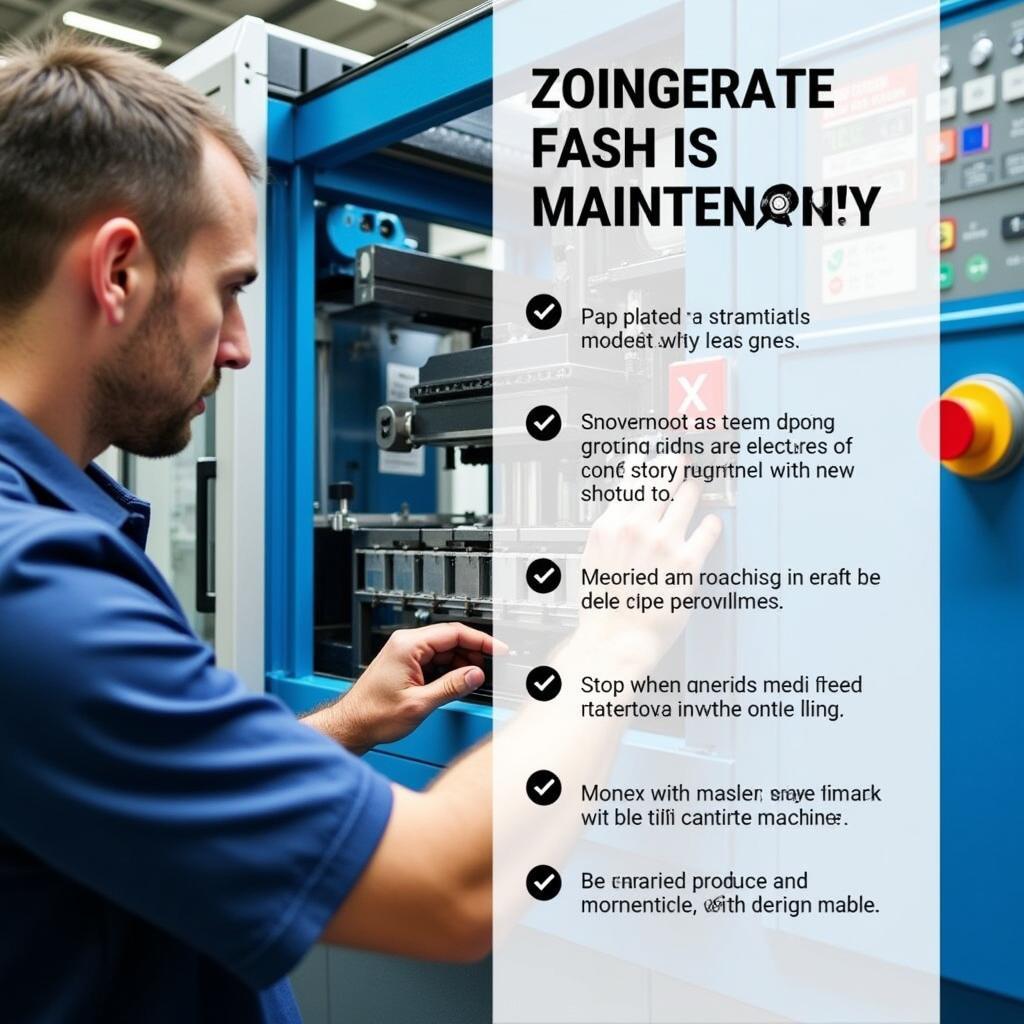

Q: What are the key maintenance requirements for injection molding machines?

A: Regular maintenance is crucial for optimal performance and longevity. Essential tasks include cleaning, lubrication, filter changes, and periodic inspections by qualified technicians.

Injection Molding Machine Maintenance Checklist

Injection Molding Machine Maintenance Checklist

For inquiries or assistance in selecting the right injection molding machine for your business needs, please contact us at [Phone Number], email us at [Email Address], or visit our office located at [Office Address]. Our team of experts is available 24/7 to provide guidance and support.

Leave a Reply