Sandwich panels are becoming increasingly popular in Pakistan for a variety of construction projects. This comprehensive guide will delve into the factors influencing sandwich panel prices, the different types available, and their applications. We’ll also provide valuable insights to help you make informed decisions for your next construction endeavor.

Understanding Sandwich Panels

Sandwich panels consist of three layers: two outer layers, typically made of metal, and an insulating core sandwiched between them. This unique construction provides exceptional strength, insulation, and lightweight properties, making them ideal for various applications.

Factors Affecting Sandwich Panel Prices in Pakistan

Several factors influence sandwich panel prices in Pakistan. Understanding these factors will help you estimate costs and choose the best option for your budget.

- Material: The type of material used for the outer layers and core significantly impacts the price. For instance, polyurethane (PUR) and polyisocyanurate (PIR) cores offer better insulation than expanded polystyrene (EPS) but come at a higher cost.

- Thickness: Thicker panels offer higher insulation values, which can increase the price. Your specific needs, such as temperature control requirements, will determine the appropriate thickness.

- Size and Design: Standard-sized panels are typically more affordable than custom-made options.

- Supplier and Location: Prices can vary between suppliers and locations. It’s essential to compare quotes from multiple vendors.

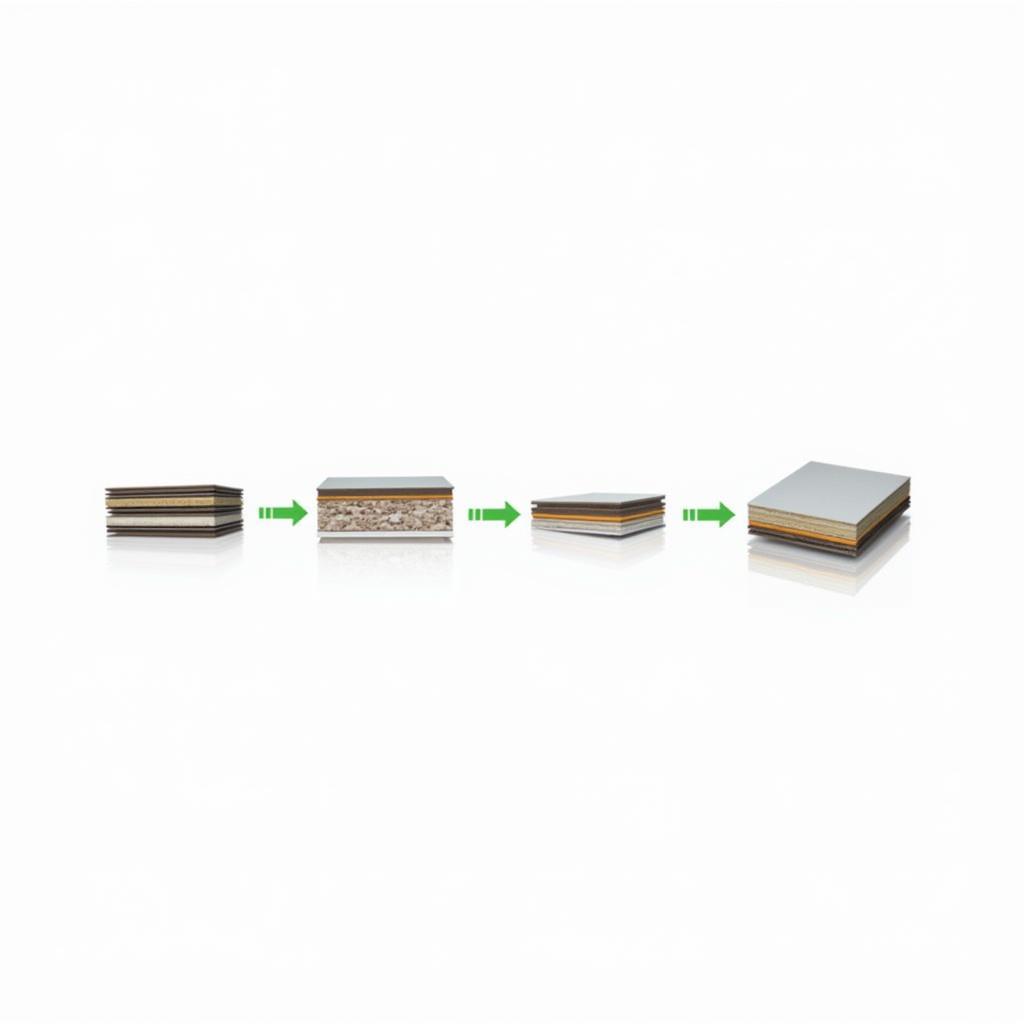

Manufacturing process of sandwich panels

Manufacturing process of sandwich panels

Types of Sandwich Panels Available in Pakistan

The Pakistani market offers a range of sandwich panels to cater to diverse needs:

- EPS Sandwich Panels: These panels use expanded polystyrene (EPS) as the core material, known for its cost-effectiveness and good insulation properties.

- PUR Sandwich Panels: Polyurethane (PUR) core panels offer superior insulation and fire resistance compared to EPS panels.

- PIR Sandwich Panels: Polyisocyanurate (PIR) core panels provide exceptional insulation and fire performance, making them suitable for demanding applications.

- Mineral Wool Sandwich Panels: These panels use mineral wool as the core, offering excellent fire resistance and acoustic insulation.

Applications of Sandwich Panels

Sandwich panels have revolutionized the construction industry in Pakistan. Their versatility, durability, and ease of installation make them suitable for a wide range of projects:

- Industrial Buildings: Warehouses, factories, and manufacturing plants benefit from the excellent insulation and quick installation offered by sandwich panels.

- Commercial Buildings: Shopping malls, offices, and restaurants utilize sandwich panels for their aesthetic appeal and energy efficiency.

- Cold Storage Facilities: Sandwich panels are ideal for creating temperature-controlled environments, crucial for food preservation and pharmaceuticals.

- Prefabricated Homes: The lightweight and prefabricated nature of sandwich panels makes them suitable for constructing modern, energy-efficient homes.

A modern office building constructed with sandwich panels

A modern office building constructed with sandwich panels

Making Informed Decisions for your Project

- Assess your Needs: Determine the specific requirements of your project, including insulation needs, fire ratings, and budget constraints.

- Consult with Experts: Seek advice from architects, engineers, and experienced contractors to determine the most suitable sandwich panel type and specifications.

- Compare Quotes: Request quotes from multiple reputable suppliers to compare prices, product quality, and lead times.

- Consider Long-term Benefits: While the initial investment may seem higher, sandwich panels offer long-term savings through reduced energy consumption and maintenance costs.

Conclusion

Sandwich panels have emerged as a game-changer in the Pakistani construction industry. Understanding the factors influencing sandwich panel prices, the different types available, and their applications will help you make informed decisions for your projects. By choosing the right sandwich panels and working with experienced professionals, you can benefit from cost-effective, durable, and energy-efficient construction solutions.

FAQs about Sandwich Panels in Pakistan

1. Are sandwich panels fire resistant?

The fire resistance of sandwich panels depends on the core material. PIR and mineral wool panels offer superior fire resistance compared to EPS panels.

2. How long do sandwich panels last?

Sandwich panels can last for several decades with proper installation and maintenance.

3. Can sandwich panels be customized?

Yes, manufacturers offer customization options for size, color, and finish to meet specific project requirements.

4. Are sandwich panels environmentally friendly?

Many sandwich panels use recyclable materials and contribute to energy efficiency, making them a sustainable building material.

5. Where can I buy sandwich panels in Pakistan?

Numerous suppliers and manufacturers across Pakistan specialize in sandwich panels.